Project

ABOUT THE PROJECT

The FASTEST project aims to address these challenges by developing and validating a fast-track testing platform that integrates a strategy based on Design of Experiments (DoE) and robust testing results, combining multi-scale and multi-physics virtual and physical testing.

This platform will accelerate battery system R&D and enable the design of more reliable, safer, and longer-lasting battery systems. Designed with a user-centric approach, the platform will manage requirements for specific applications and battery systems or subsystems, ranging from the entire pack to individual modules, cells, or materials.

Project Key Research Areas

Fast-Track Hybrid Testing Platform

DT Structure for Information Management

The Virtualisation of Characterisation Experiments

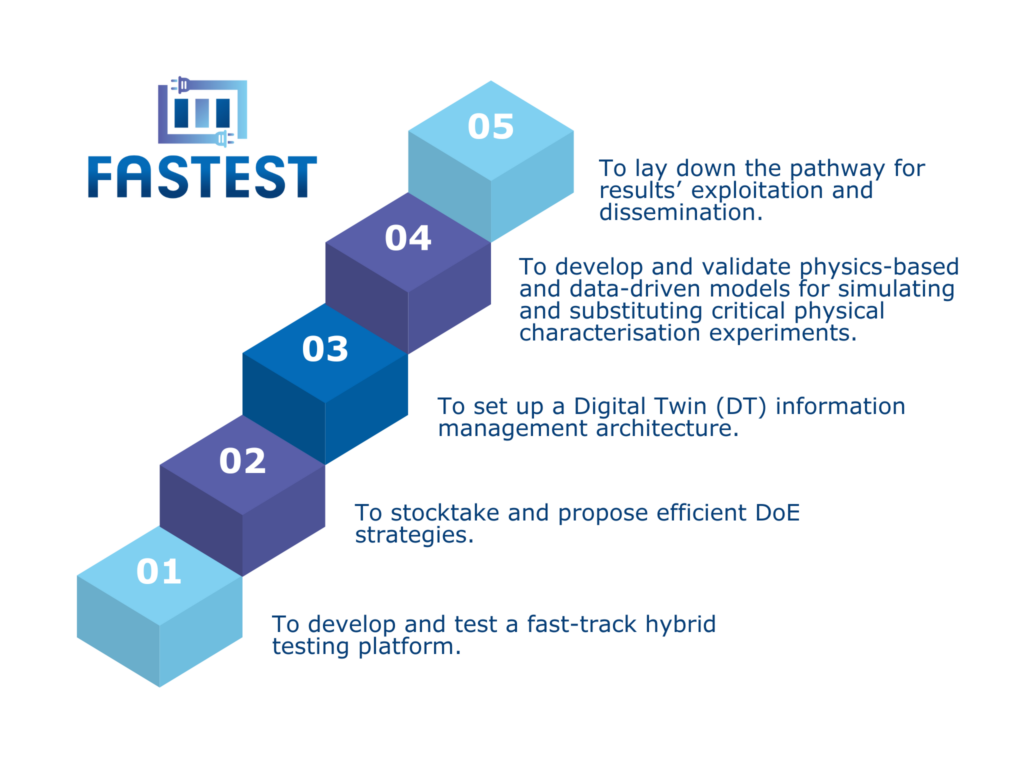

OBJECTIVES

The platform will combine virtual and physical testing across multi-scale and multi-physics domains to accelerate battery system research and create safer, more reliable, and longer-lasting battery designs.

The project introduces a holistic hybrid testing approach, incorporating smart DoE algorithms, virtualized benches, and digital twin data to elevate testing efficiency and effectiveness across global testing facilities.

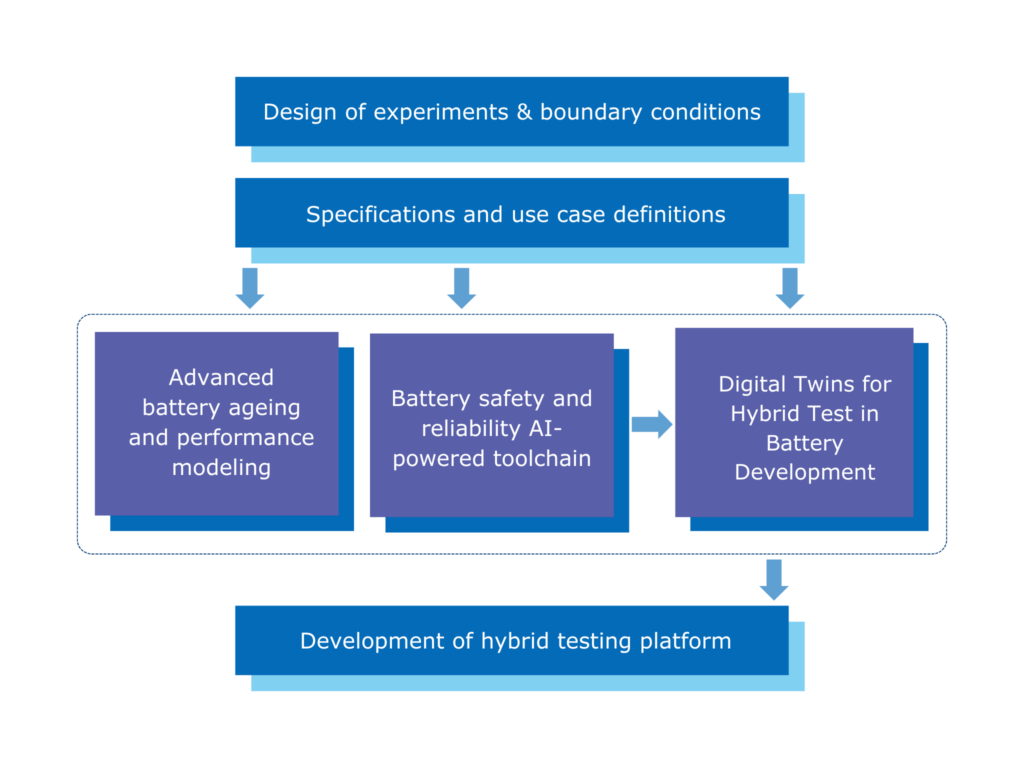

METHODOLOGY

The FASTEST project outlines a structured plan to create and optimise a hybrid testing platform for battery research and development.

This initiative involves defining battery requirements, tailoring design-of-experiments methods, building and validating virtual models, creating standardized data templates for battery systems, and developing the technical aspects and architecture of the hybrid testing platform. The ultimate goal is to establish an efficient and effective testing environment that advances battery R&D.